All you Need to Know about UV Resin

UV resin cures by the energy of ultraviolet irradiation devices. Just like epoxy resin, polyurethane resin or acrylic resin is an industrially produced synthetic resin. As with all synthetic resins, the field of application determines whether the resin is suitable for your project. UV resin allows fast a processing time and uncomplicated application, but can only be used for coating because of its short durability.

UV Resin vs Epoxy Resin

The product properties and uses of UV resin and epoxy resin differ widely. EPODEX offers 2-part epoxy resin, which is mixed of a resin and a hardener component. In contrast, UV resin is a 1-part resin that is instantly ready to use. Epoxy resin cures without any aids, UV resin only cures under UV irradiation. Its maximum layer thickness is 1mm. Epoxy resin allows layer thickness of up to 5cm per casting, on the other hand. UV resin always requires a UV lamp to cure and is therefore only suitable for smaller areas. Epoxy resin can also be applied on large surfaces, such as industrial floors.

You should always wear a dust mask when working with both resins. While epoxy resin is emission-free once it is cured, UV resin continues to evaporate. The durability of UV resin is limited to half a year. Furthermore, it is neither heat- nor scratch-resistant. Epoxy resin is the best choice for a durable, long-lasting result that is also aesthetically pleasing for a long period of time. If durability does not play a role and you need fast curing speeds, you can use UV resin.

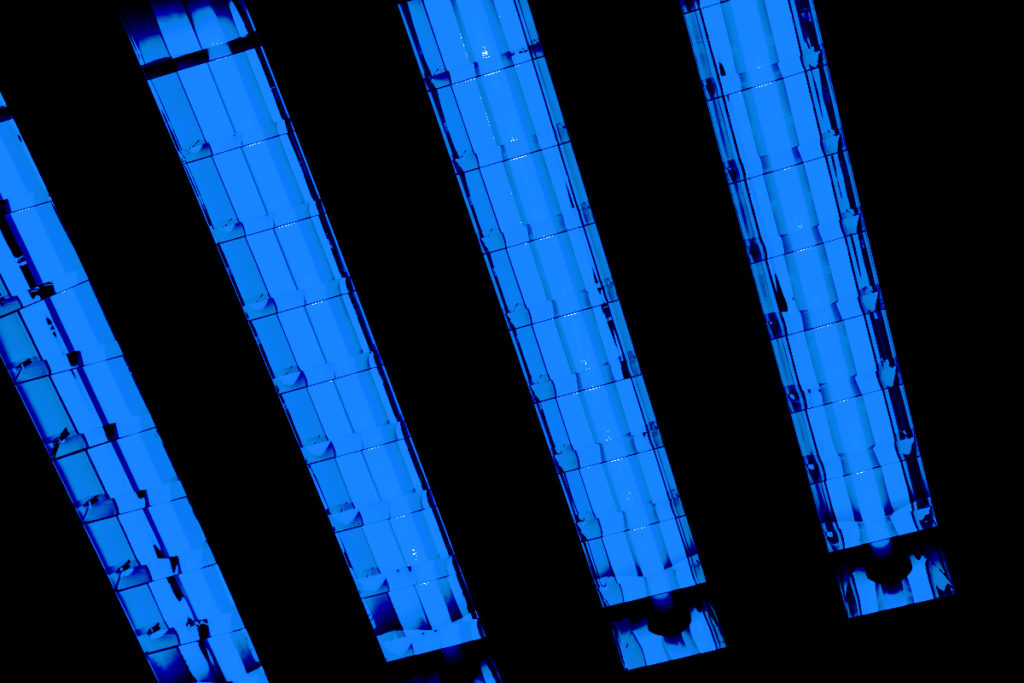

Application of UV Resin

The application of UV resin is relatively simple. You just brush it to the area to be coated or glued in a thin layer and you can also mix in colours or create patterns. When the coating is done, you can start the curation process with an UV lamp or UV flashlight with at least 4 watts. Depending on the layer thickness and the lamp’s power, the resin cures in maximally 3 minutes. You can then apply further layers in the same way. During application you should always wear a mask. However, even after UV resin has cured it still produces vapours you should not inhale.

TOP ratings

- Als Epoxidharz-Neulinge waren wir im ein oder anderen Punkt unsicher. Das Team von Epodex hilft mit Geduld, Freundlichkeit und perfekter Fachkompetenz weiter. Absulute Empfehlung, top Service, super Lieferzeiten!!! 22.08.2019

- Bin rund um zufrieden, sehr gute Produkte und besonders kundenfreundliche und schnelle Lieferung! Werde bei Epodex auf jeden Fall wieder einkaufen! 23.08.2019

- Guten Tag! Ich würde EPODEX auf jeden Fall weiterempfehlen da es von der Bestellung bis zur Lieferung nur 3 Tage gedauert hat und auch die Bestellung war super einfach und problemlos. Und ich werde auch weiterhin bei Ihnen bestellen. 14.08.2019

Pros and Cons of UV Resin

Depending on the field of use, UV resin can be the best choice because of its high curing speed of 1-3 minutes (depending on the thickness of the layer). It has no pot life and can be applied for a much longer period of time than acrylic resin. Unlike a surface with epoxy resin coating, it is not permanent. The durability of a surface coated with UV resin varies between a few weeks and half a year. Since it only allows casting depths of up to 1mm, UV Resin is no casting resin. A thicker casting would form bubbles and voids. Even after curing, UV resin is still very sensitive to heat and can flake off or blister in the sun. Due to its properties, it is well suited for jewellery or ornamental elements, however. You can also use it as glue.

Buy UV Resin

You can buy UV resin online or in the stationary trade nearby, where you will also find other equipment like brushs, gloves or a dust mask. UV resin itself is often available at a low price, but keep in mind that you will also need an UV lamp, which can be rather expensive and only pays off, if you work with UV resin regularly.

Jewellery Made of UV Resin

UV resin is often used to create small pieces of jewellery, where the product properties come in handy. UV resin allows you enough time to create filigree patterns before the resin has cured. The small dimensions of jewellery also facilitate curing under a UV lamp. For a long-lasting durability of your jewellery, we recommend to seal the UV resin once again with an epoxy or polyurethane resin layer.